Applied innovation key to speeding green steel shift: Timo Haimi

New, and some old, technology will play a major part in decarbonisation drive

Metso’s’ Timo Haimi is increasingly optimistic about prospects for accelerating the world’s green iron and steel revolution, with a couple of key caveats.

The Helsinki-based veteran of global minerals and metals processing player Metso sees government and company mandates and technology advances pushing the two-billion-tonnes-a-year global steel industry onto a carbon-emission reduction highway. The iron and steel sectors combined are said to account for circa-8% of the world’s anthropogenic CO2 emissions.

Steel-making efficiency improvements, increased use of scrap in production and breakthrough process innovations are seen as keys to the industry’s decarbonisation shift.

It’s a transition that, as some have said, could shift “the geography of steel”. And it certainly opens up significant opportunities for major iron ore exporting nations such as Australia, where Haimi will deliver an important address at IMARC in Sydney next month on green iron smelting technology for Australian iron ores and where Metso is working with Rio Tinto on BioIron low-carbon ironmaking and other projects.

On the process innovation front BioIron is a pilot-scale initiative aimed at using biomass and microwave energy to produce reduced iron.

Hydrogen-based direct reduced iron, or DRI, is expected to become an important decarbonisation enabler for steelmakers. Direct reduction using natural gas is already producing more than 130 million tonnes of iron a year.

Depending on where and how hydrogen is being sourced it opens a door to truly green carbon-free steel, but scaling hydrogen availability and lowering costs are key to acceleration of its use.

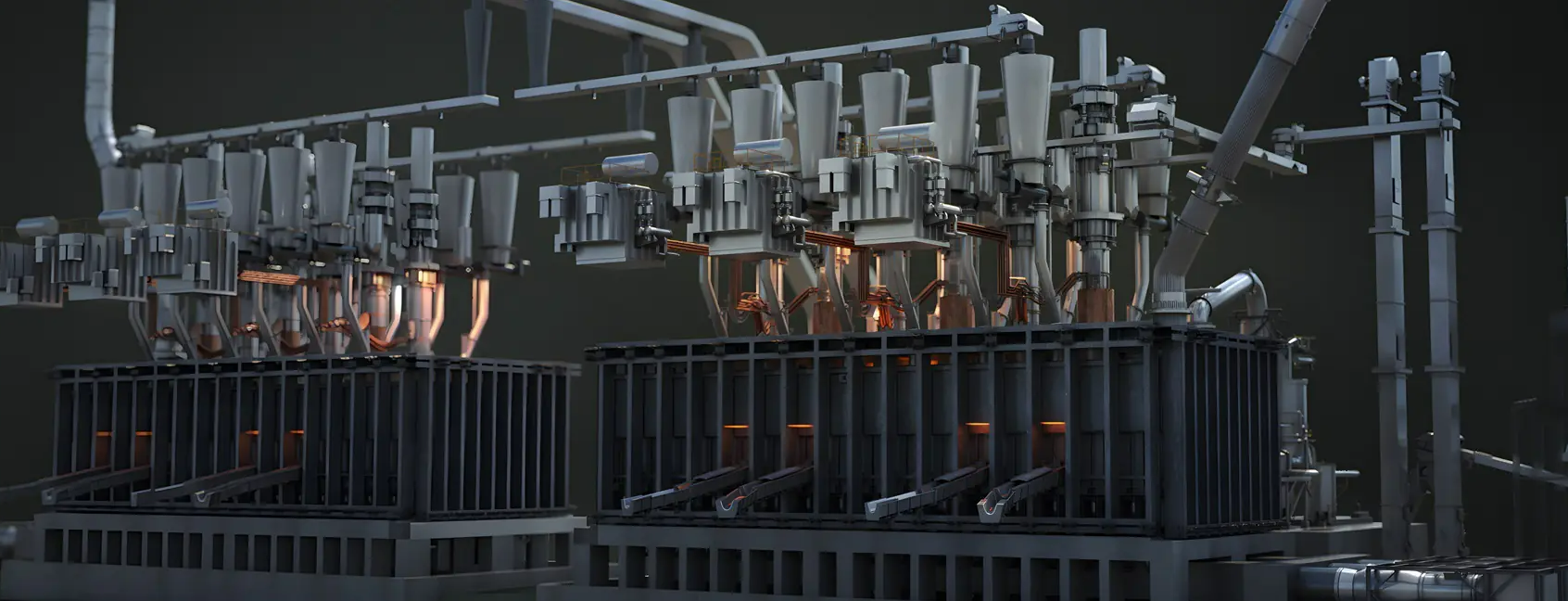

Haimi will talk in Sydney about Metso’s Circored direct reduction process and DRI Smelting Furnace, innovations that have come out of many decades of mineral processing and refining research and development complex that has produced the copper flash smelter among many other advances.

“In the case of Circored there has been decades of development already,” he says.

“Renewed interest is driving accelerated development which will see the technology being applied to different ore types and in combination with other technologies to deliver scale benefits.

“The DRI Smelting Furnace is based on the same proven technologies that we have been using for decades in multiple smelting projects, but for different metals. We are already processing hundreds of tonnes of feed materials in our smelters.

“So only the feed material, the DRI, is new for the process, which is why we are doing internal and external pilot testwork to prove this process.

“But compared to other new technologies we are well advanced.

“The road to a one million tonnes per annum [DRISF] plant is not far away.”

Haimi says Australia has potential for massive upscaling of current renewable energy production and green iron is one application for the energy.

“An obvious route is iron ore reduction using gas – natural gas or hydrogen – to produce DRI,” he says.

“Hydrogen production does require a lot of energy and that is preferably going to be from the renewable energy that is coming.

“The challenge for Australian iron ores is that traditional DRI – and electric arc furnace – steelmaking has a requirement for high-quality DRI with low gangue content. This disadvantages most Australian iron ores.

“The beneficiation teams in the Minerals business of Metso are reporting more and more interest for further beneficiation everywhere … but some of the ores globally just cannot be beneficiated enough, or it cannot be done feasibly.

“And for these challenging iron ores we come into the picture with our hot beneficiation [DRISF] technology.”

Haimi says scaling up hydrogen-fuelled DRI to cut carbon-fuel based blast furnace reduction and then using grid electricity (powered by more renewables) in a smelting furnace to melt the DRI to produce green steel can ultimately put a massive dent in the US$1.4 trillion iron and steel sector’s carbon emissions profile.

“The next step is to scale up this transformation and make available these new technologies that can utilise iron ore with higher gangue amount,” he says.

“Otherwise it can be really problematic to replace the carbon consuming blast furnace and then more than half of the steel globally cannot be decarbonised.

“Unless some other technology makes giant leaps in their development.

“My biggest concerns are the available amount of renewable energy and then also the available capacity of smelting plant suppliers. We are currently operating in a business [non-ferrous and ferroalloys] that is 100 times smaller than the steel business.

“Can we, who are already operating in this new technology area, scale up our organisations and capacities quickly enough?”

In response to this conundrum, Haimi says one example of industry collaborating to solve a global challenge is the BioIron project

“One of the world’s leading mining companies working together with a number of OEMs shows how we can leverage the various capabilities already available,” he says.

For more information and to register for IMARC 2024, please visit the IMARC Website.

About IMARC: Collaborating on trends in mining, investment and innovation towards a sustainable future

IMARC is the premier gathering for the most influential minds in the mining industry, a dynamic hub where ideas ignite, and inspiration flows – it is the ultimate meeting ground for global industry leaders. As Australia’s largest and most significant mining event, IMARC attracts over 9,000 decision-makers, industry leaders, policymakers, investors, commodity buyers, technical experts, innovators, and educators from more than 120 countries. For three action-packed days, attendees will engage in cutting-edge learning, forge valuable deals, and experience unparalleled networking opportunities.