Efficient and accurate ventilation surveys for model calibration (extract)

This is an extract from the paper 'Efficient and Accurate Ventilation Surveys for Model Calibration' presented at the International Mine Ventilation Congress 2024, co-hosted by AusIMM, UNSW Sydney and the Mine Ventilation Society of Australia.

Introduction

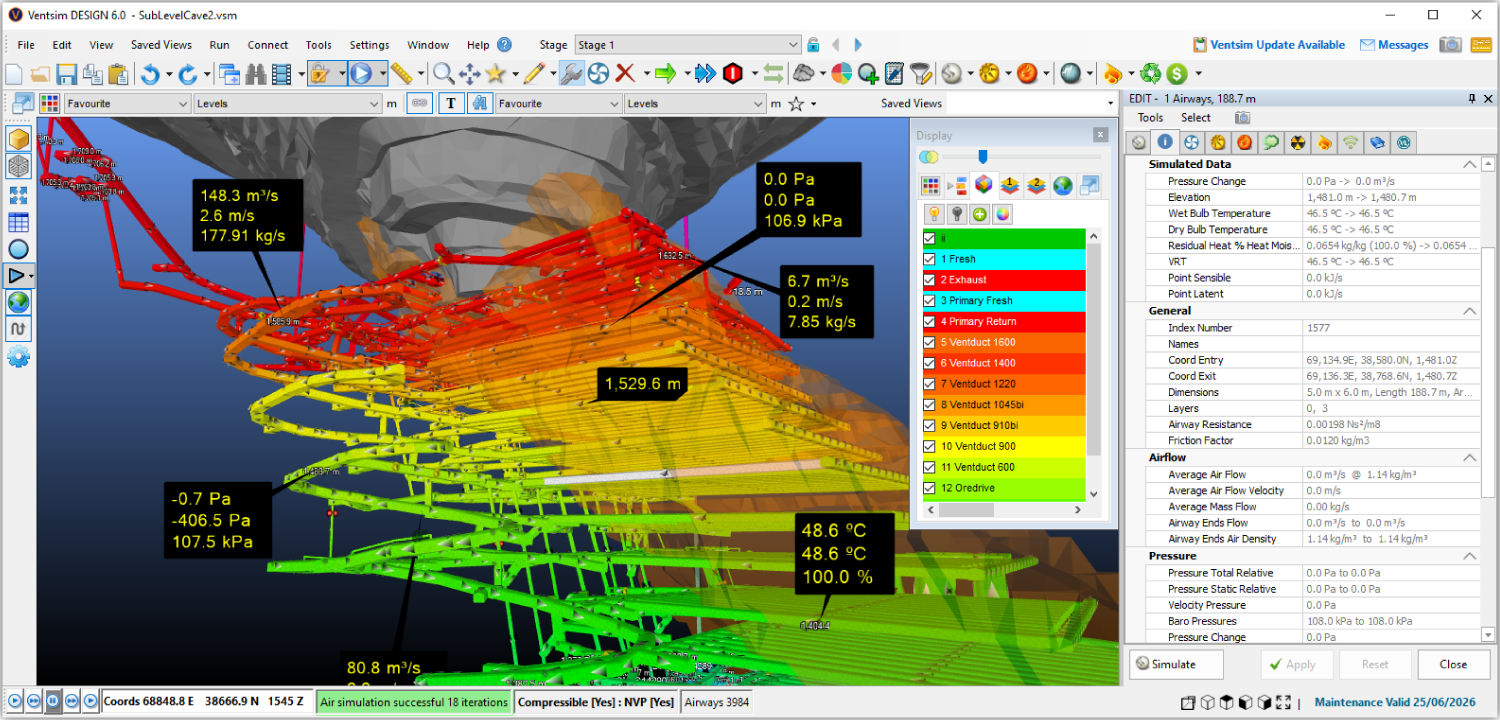

Ventilation simulation software, such as Ventsim DESIGN, is now widely used at nearly all mine sites, supporting engineers in both their daily activities and long-term planning. Most engineers have a reasonable knowledge of simulation software; yet as many ventilation engineers with different backgrounds modify a model, its quality may decrease as the reasons for certain changes or settings within the model become obscure with time.

When predicting the future requirements of a new mine or extension, an engineer can only use academic references and experience to estimate the resistance of the mine. However, with an existing mine, more information is available. Ensuring the model used is well-calibrated and up to date is an essential part of the role of the site ventilation engineer.

Accurate ventilation models are critical to calculate the operating points for primary fan selection or heating or cooling solution selection. Considering the cost of such equipment it is critical to avoid miscalculations leading to disastrous consequences, both in economic and production delay terms, if the equipment is not selected appropriately.

This article does not intend to provide a method for an exact calibration with no error; rather it aims to provide a method that relies on the minimum time required for sufficient accuracy.

Case study examples

Several examples of the consequences of poorly calibrated models are presented below. The personnel names and mine locations have been anonymised.

Case A - poor fan duty calibration despite correct airflow

A mine claimed their model was accurate and showed good correlation to actual airflow with most readings being within 10 per cent of the model. However, further investigation highlighted that the surface fan operating pressure was double the modelled value.

In this case, the mine resistance was grossly underestimated but the steep fan curve permitted close correlation with measured flow. Using this model to plan for future installation would have likely caused the main fan to stall earlier than expected and the expansion to be stopped.

Case B - poor pressure calibration despite correct fan duty

A mine model's main fan duty (flow and pressure) appeared accurate. During an emergency, it was decided to open a bulkhead to allow additional airflow through. The model suggested a significant pressure against the bulkhead of 400 Pa which should have provided good airflow when opened. However, when measured underground, the pressure was found to be only 10 Pa and the opening did not offer the help they hoped.

The emergency team had gone underground with an action plan based on information that wasn't accurate and would not work, potentially endangering personnel.

Case C - the model is calibrated against assumed data

A model was developed remotely using data provided by the site. The model never matched actual measurements and pressure anomalies were present that were never fully accounted for. The offsite engineer used the model to recommend new surface fans in a new mining area of the operation; however, once the new fans were commissioned, they immediately stalled.

The engineer visited the site and upon inspection of the existing main fan, he discovered that the blade angle provided in the original data by the site was very different from the one in use. Fortunately, making changes to the operating curve of the main surface fan (ie operating on a lower curve) allowed a system pressure reduction at the new fan installation, allowing these new fans to function within their design curve and without stalling.

By relying on unverified information provided solely by other parties, the study could have had a significant impact on the production if no solutions were found.

Characteristics of a good model

Accurate

A good model needs to represent the mining operations reality accurately. Most would consider a 10 per cent maximum discrepancy in airflow and pressure (difference between measured and modelled) to be reasonable. Any model within 5 per cent would be considered very high accuracy given the limitations and variability of survey measurements. Airflow alone however does not offer enough information to understand the mine resistance and pressures at the main fans and ventilation control devices (VCDs) are critical to understand the mine resistance.

Replicable

A traditional method of building a model is to measure airflow and pressure loss between every junction in a mine (a 'PQ' pressure quantity survey) allowing the engineer to calculate exact resistances (and any inherent shock losses) and derive accurate friction factors if required. A model built correctly this way should be highly accurate, yet it may be difficult for other users to understand, maintain and extrapolate due to previously measured resistances not being suitable for new development. The high turnover of ventilation engineers at many mines exacerbates this problem.

A model with standardised friction factors and resistances (calibrated against a sample of in situ measurements) may be slightly less accurate but will be able to be more consistently maintained by different engineers and provide more reliable guidance for future designs and modelling.

Ease of use

Mines are often complex and airway locations can be easily mistaken for others. Modern ventilation modelling software utilises 30 graphics and colours that can assist the user in better understanding the underground ventilation environment. A good model should be easy to comprehend and interpret, with colours, shapes, sizes, layers, animations, and locations representing important information for key parts of the model.

For example, intake and exhaust circuits can be coloured to differentiate air types, and essential data such as quantity, pressure, and temperature can be shown as needed. Dense textual data in large models can be confusing and should be reserved for in-depth analysis only when needed in key parts of a model. Additionally, sources of critical assumptions and factors should be referenced in the model (eg reports, textbooks, measurements).

Useful

Statistician George E Box stated that 'All models are wrong, but some are useful.' In that sense it is important to understand the purpose of the initial model. At times a quick model can give you the answers you need but potentially cannot be used for future work. One exception to this is a mine base model which should be kept up to date and fully calibrated. Such a model is often used by the site engineer to troubleshoot future changes, simulate diesel or fire. It will also be sent to consultants to provide advice in the long-term. Such a model needs to be kept accurate as many will assume it right.

Accuracy can be achieved in many ways, but can sometimes be mimicked by adjusting the wrong parameters. Models are usually used to test what is going to happen before it does, so the true test of a good model is its ability to predict the results of ventilation changes. To do so, a ventilation change such as an open door or a fan turned off would be simulated then measured and both should be within the same accuracy as the initial model. For a mine base model, this should happen naturally, and investigation should take place if the model failed to predict the change.