Eight steps to achieve optimal results from your grade control system

Grade control is an integral part of both open pit and underground mining operations. Monitoring ore quality while controlling the grade and variability of a deposit is essential for mining companies to maintain accurate grade information. This helps determine mine plans, resource deployment, and ultimately, the mine's return on investment.

Grade control is not merely the responsibility of geologists. It spans multiple stages of the mining value chain, including data collection, interpretation, modelling and the production of practical excavation plans. In addition, there may be stockpile sampling and checks at key points, including belt samples, truck samples, face samples and a daily/weekly/monthly reporting and reconciliation stage.

A well-implemented grade control system can help minimise dilution, maximise recovery, improve reconciliation between predicted and actual production, establish consistency of procedures, ensure continuity of knowledge, and increase collaboration between geology, planning and production. On the other hand, ineffective grade control can lead to a reduction in the overall efficiency and profitability of a mining operation.

Although every site defines grade control differently through tasks and processes specific to that operation, there are some general best practices to maximise efficiency and achieve the best results from your grade control system.

1. Establish a consistent, repeatable and customisable framework

Proper planning is key to a successful grade control system. Establish step-by-step workflows and specific preset parameters in the early stages of the grade control planning process. This helps ensure consistency in routines and sets expectations around outcomes. As you move into later phases of the mining cycle, your framework can be adapted to meet the changing needs of your operation.

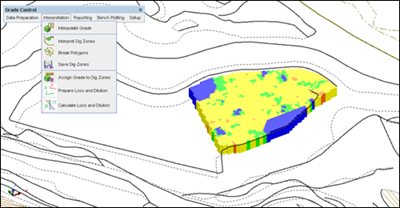

A simple menu-based interface with step-by-step workflows ensures a consistency of grade control procedures.

2. Document your workflows

Once you have established your framework, create written step-by-step procedure documents. Not only does this allow you to validate your workflows and parameters with other departments and facilitate internal alignment, but it also helps provide training and reference material to grade control staff.

Make sure to regularly update your documentation as changes and refinements are made to the workflow. This will greatly assist in knowledge transfer resulting from resignations and retirements to new staff that require onboarding.

3. Validate your data

Your grade control system is only as good as the data that enters it. Maintain good data hygiene by ensuring your data is valid and robust before incorporating it into your grade control system. This includes performing an effective quality assurance/quality control (QA/QC) process to ensure accurate and reliable sample data.

Sometimes this can be performed within the database itself upon entry of the data, depending on the platform you use. You’ll get the best results from automating the process to save time and reduce errors.

4. Enforce consistent interpretations across your team

Consistency is essential when interpreting grade information. Any slight deviations in the rules and parameters used to delineate dig areas, for example, could have big consequences, potentially leading to increased ore loss and dilution.

Instead, grade information should be classified and coloured according to specific ranges and cut-offs to facilitate the interpretation process. To do this, you’ll need to establish specific guidelines and rules when delineating interpolation domains and dig limits. Depending on the software you use in your grade control system, this process can be automated.

5. Work from a single source of truth

Too often, the latest grade control data is not readily accessible to all team members and departments. Rather, it’s maintained in a static document on a local hard drive. And even if the document is shared with relevant team members, it becomes outdated as soon as the original is updated.

Today, there are digital platforms that can ingest, integrate, or index data to ensure that all team members always have real-time access to relevant data. This visibility not only assists with internal validation and alignment, but it also improves and accelerates decision-making.

6. Facilitate collaboration

Along with a single source of truth, collaboration between team members and departments is vital for making proper decision making. It’s best to have open lines of communication between all team members, whether they’re on the same team or not. Some advanced business platforms will have collaboration features built in that make this process a breeze. Even without this, it’s important to break down any silos that exist between departments and encourage team members to review documentation and provide feedback in an open and honest manner.

7. Centralise and structure your data storage

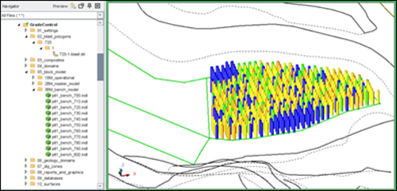

It may seem basic, but make sure to establish structured data storage guidelines and effective file naming conventions. There’s nothing worse than data that can’t be found because of a messy file structure or a file name no one can interpret. Creating proper naming conventions will ensure consistency, improve searchability and enhance the accessibility of data. It also helps to enable automation, which can result in significant time savings for you and your operation.

Centralised and structured data storage and file naming conventions.

8. Don’t neglect reconciliation

Finally, reconciliation is a must in any operation. On a regular basis (e.g., monthly or weekly), compare your actual production with the predicted results of the grade control system. If there are no issues, you can confidently move forward with your mine plan. If there are discrepancies, fine tune your workflows, parameters and settings to improve future grade and tonnage predictions. Regularly performing material reconciliation will help keep your operation on target and profitable while helping you adapt to any changes that may occur throughout the life of mine.

Consider an advanced business platform

A well-functioning grade control system provides a clear understanding of grade variations and allows for improved decision-making to drive profitability.

With recent technological advances, it’s possible to find further efficiencies using a digital platform such as GEOVIA Surpac’s grade control system, which can simplify what can be a very complex process through automation in a step-by-step framework, resulting in significant time savings. A simple menu-based interface is easily configurable and ensures a consistency of procedures with centralised and structured data storage.

However you decide to manage your grade control system, make sure it’s consistent, well-documented, flexible and accessible to help minimise dilution and maximise ore extraction.

Find out more

If you would like to learn more, please visit the GEOVIA website at https://www.3ds.com/products/geovia/surpac