Improving mining water management

There is an abundance of water on our planet – over 70 per cent of Earth’s surface is water – but most of that water (97 per cent) is salty, with only about three per cent fresh water.

Of the fresh water, 77 per cent is in the form of ice and snow, 22 per cent is stored below ground in aquifers and in the soil, and only about one per cent is readily available in lakes and rivers.

While we have a great amount of water on Earth, only a small amount is available for humans, agriculture and industry. With demand increasing potentially up to twice as fast as population, reliable water supply, efficient use and effluent management are critical to success (See this article from the US Government National Intelligence Council’s Strategic Futures Group: The Future of Water: Water Insecurity Threatening Global Economic Growth, Political Stability).

In Australia in 2021-22, the mining industry extracted 1,411 gigalitres of water, around a 5% increase on 2020-21 figures. This represented around 2% of the total water extracted from the environment (both household and industry use). More information can be found on the ABS website here. While mining may account for a small percentage of total water use, water is crucial for mining operations. In regions with extensive mining operations, mining can be the primary consumer of water.

Increasingly scarce and tightly regulated supplies, along with increased competition for human, agricultural and other uses, are causing mines to look for alternatives. There are opportunities to learn from research and other industries that may help us manage this resource better in the mining industry.

Desalination is one method, albeit an expensive one, to turn salt or brackish water into potable water.

Research driven by the scarcity of clean water and the cost of SWRO (Seawater Reverse Osmosis) is being done at CSIRO (The Commonwealth Scientific and Industrial Research Organisation). Its goal is to determine where salt water can be used in mining, including crushing, grinding, flotation, and separation. The studies tend to focus on the saline concentration of the water and how that impacts the chemistry of the operation.

As just one example, in northern Chile, seawater is pumped tens of kilometres to mine sites at higher altitudes. Direct use of salt water and desalination can certainly help, but the cost of transportation and treatment of salt water may be prohibitive in some cases.

We also know that the high concentrations of salt can also impact the life of the processing equipment through accelerated corrosion. Experience with salt water gained in marine, offshore platforms and SWRO water treatment plants can be applied to saltwater systems in mining.

These industries have dealt with the corrosive issues of salt water for decades and have learned over the years where they can get away with standard practices, and where they are better off investing in more corrosion resistance. A critical failure in a reverse osmosis system can shut down the drinking water of a city. A failure on an offshore oil platform can scramble resources to transport replacement parts and technicians via helicopter to make the repair. Identifying where salt-water corrosion can affect the plant and taking the steps to eliminate those types of failures has made a big difference in these operations.

Typically, carbon steel and 316SS (stainless steel) materials are routinely used in mining systems. The introduction of saltwater forces the mines to take a closer look at corrosion resistance.

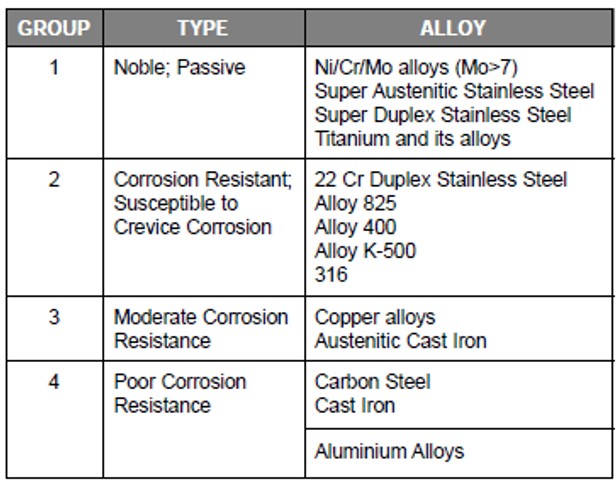

Table 1 is taken from the UK Department of Trade and Industry publication, 'Bimetallic Corrosion'.

In general, alloys in Group 2, including 316 are acceptable for use in seawater. These alloys have low corrosion rates but are susceptible to crevice or weld corrosion in seawater. In applications where a small amount of corrosion can impact the performance of the system the mine may want to consider moving to an alloy in Group 1.

Group 1 contains passive alloys, which adopt electropositive potentials in seawater. These applications could include critical mechanical clearances, sealing surfaces, or instrumentation where relatively minor corrosion could result in a leak, error, or cause premature failure. Moving to Nickel Alloy C-276, Super Duplex Stainless Steel or Titanium in these cases can significantly reduce corrosion related issues.

As we face the challenges ahead, we should take advantage of the experience gained by others to reduce our learning curve.

Of course, it is also helpful to consider solutions for mining issues, such as production challenges caused by major operational problems from water pumping pipeline leakages, which can cause operational problems resulting in unscheduled shutdowns, production loss, and potential environmental damage. By implementing condition monitoring for water pumping, miners can mitigate these issues.

And when it comes to pit dewatering, miners are faced with the need to improve reliability of open pit dewatering units to minimize operational disruption and improve the efficiency of manually operated dewatering unites. Poor valve life due to solids content, pH level, corrosive and abrasive service is also an issue.

By implementing purpose-engineered automated isolation valves to enhance performance and operational life, miners can get a handle on these issues and improve operational reliability.

Mining is one of many industrial applications where water management has become crucial to profitability. And, there are opportunities to learn that may help us manage this resource better.