Project and operational readiness for mining projects

Project and operational readiness for mining projects: what is this all about, and how hard is it to achieve success?

By addressing these questions, I hope to prompt further discussion, raise standards and help improve the delivery of mining projects. This is the first in a planned series of articles that will look at this topic in detail.

Defining and implementing mining projects

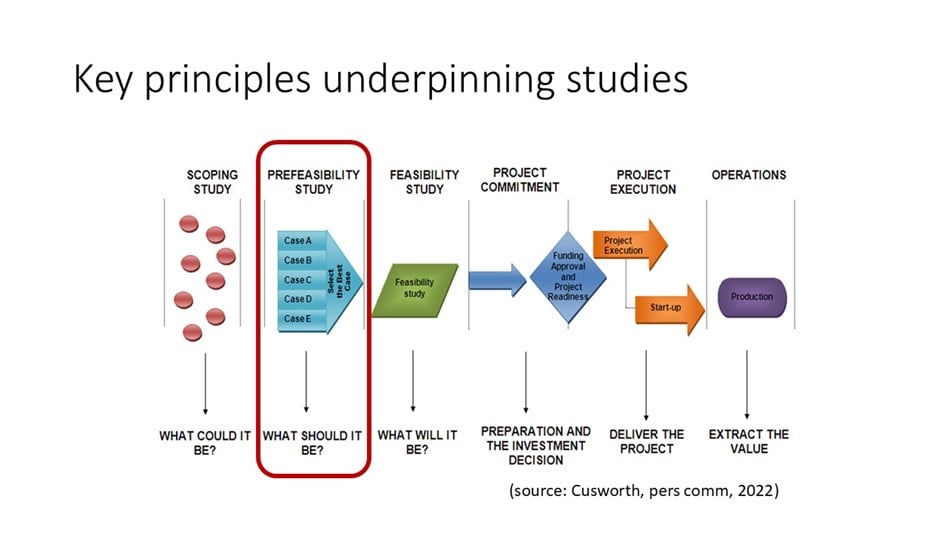

The principles for defining and implementing mining projects are widely accepted and are shown in Figure 1 (Cusworth, 2022). These principles apply to large and small projects alike, and every successful new mining operation depends on the satisfactory execution of this workflow. 'The work is the work,' and attempts to shortcut or work around it can add risk to a project.

Figure 1: Key principles that underpin the basis of studies (source: Cusworth 2022).

Timeframes for project development vary, depending on the following:

- a project’s maturity, its scale, and complexity

- the continuity and integrity of proceeding work

- the owner’s needs and familiarity with the project’s setting and mineral commodity.

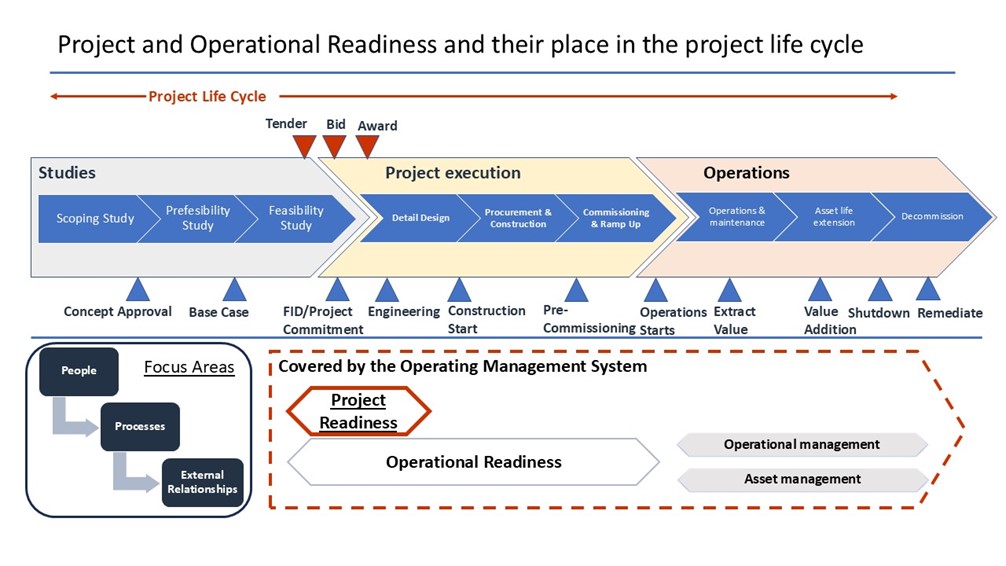

This workflow (studies, project execution and operations) has internal waypoints or gates (Figure 2). By working through this process, a project’s proponents progress the definition and delivery of the project's physical components. Project and operational readiness capabilities are needed to support the last two phases: project execution and operations. These capabilities depend on the owners’ people, the processes they apply and the relationships they can build.

Figure 2: Project and Operational Readiness and their place in the project timeline (after Jahnig 2016; source: Pratt 2023).

Addressing performance issues for mining projects

The inability to satisfactorily complete or address the first two project development phases shown in Figure 2 can contribute to capital cost blow-outs, construction delays, and underperformance in operations.

McCarthy (2003) reports that problems during commissioning and operations can be tied back to the technical work of the feasibility study (FS) and Mackenzie and Cusworth (2016) concluded that failing to produce a detailed Project Execution Plan (PEP) as part of a FS was a significant issue for the construction of many projects.

The PEP ensures the owner can equip themselves with the requisite skills and capacity to deliver the project. This requires people with the necessary knowledge and processes to support the project’s execution. Therefore, ‘project readiness’ is ultimately about more than simply producing an appropriate PEP; it is about the owner and their project team’s capability and capacity to deliver the project.

As a broad concept, ‘readiness’ is described as ‘the missing, or overlooked, link between strategy, the intent and a decision to take a course of action, and the execution of that action’ (Rey, 2019). In other words, an organisation's ability to ‘walk the talk’ sets them up for success.

An owner faces similar circumstances when commencing the operations phase of a project, i.e. its ‘operational readiness’.

What does readiness require?

A starting point is for the project owner to have a clear and practical understanding of the project and its specific operational readiness requirements.

In practical terms, ‘project readiness’ refers to the capacity of the project’s owner to function as the ‘owner’ of their project; and ‘operational readiness’ concerns the work required by the operations team to ensure a new operation gets away to a good start.

Compared to the development phases, project and operational readiness for mining projects could be better defined. Operational readiness and its impact on mining project performance has some recognition in the published technical literature.

However, the role of project readiness in the performance of mining projects, and how it links to both the study and operational readiness phases, needs to be more clearly understood.

Why these critical topics attract so little interest is unclear.

However, part of the reason might be that when people think about project development, they think of its tangible aspects: e.g. studies, the establishment of mine sites and their equipment. These offer opportunities for technical discussion and debate; opportunities for decisions to be made, supported by figures, diagrams or drawings; places to visit and things to look at. This work is exciting and rewarding for the people involved; successful associations can help them build reputations and careers.

In comparison, project and operational readiness are more intangible. These concern the people, processes, and relationships needed to get work done and how these connect. For many, this work is seen as a less exciting aspect of a project and may even be boring. There is nothing to see or visit here; there are just things to do.

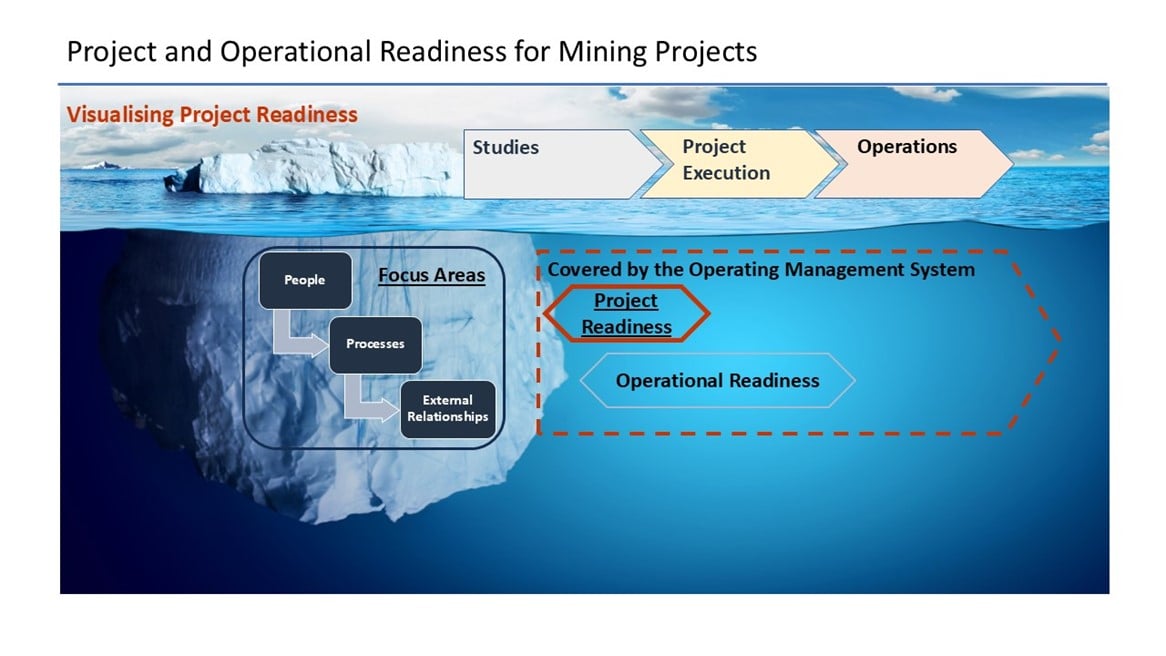

However, imagining project development as an iceberg may be helpful. What you can see of an iceberg is made possible by what you do not see, which is its volume below the water line (Figure 3).

Figure 3: Visualising project development with project and operational readiness.

Like the unseen part of an iceberg, project and operational readiness enable and influence what is seen as tangible components of a project. That is the ‘how’ aspect. An owner must address the less tangible work to competently and confidently manage their project and be ‘project ready’.

In other words, the ability of an owner to successfully deliver a project depends on:

- who they are: their identity and their business strategy and approach to risk

- their familiarity with the project scope, its scale, its location, and the requirements of the subsequent operation

- their organisational competence, and capacity to deploy people and the processes appropriate to a particular project’s characteristics.

This mix may vary with the size of an owner’s organisation, from large multinational miners to exploration companies looking to establish themselves as producers. Regardless of their size, the foundations for project and operational readiness lie in their connection with an owner’s business strategy and management structure. Both are tied to an owner’s sense of purpose, captured by their mission and vision statements and supporting values. These are, or should be, the likely foundations for an owner’s approach to constructing and establishing a new operation, defining performance measures, and achieving its strategic outcomes.

Part two of this article will discuss the connection between readiness, project and operational, and establishing the underlying logic for a business management structure for a project. This discussion will show the relationships between an operating framework, the development of an operating philosophy, the selection of an operating model, and the definition of management systems needed.

Concluding remarks

Central to successful project and operational readiness is the need for a project owner to commit resources, time, and money to address the less tangible aspects of a project. This is required so they are ready when they need to be!

References

Cusworth, N, 2022. Personal communication, 22 February 2022.

Jahnig, D and Agoston, J, 2016. Risk management – is your capital project ready to deliver business value? A White Paper Issued by The Navigant Construction Forum™ accessed 5/10/2016.

Mackenzie, W R and Cusworth, N, 2016. The Use and Abuse of Feasibility Studies – Has Anything Changed? in Proceedings Project Evaluation 2016, pp 133–148 (The Australasian Institute of Mining and Metallurgy: Melbourne).

McCarthy, P, 2003. Managing Technical Risk for Mine Feasibility Studies, Mining Risk Management Conference Sydney, NSW, 9 - 12 September 2003, The Australasian Institute of Mining and Metallurgy, pp 21 – 27.

Pratt, A G L, 2023. Operational Readiness – what is it and how to get it done? The AusIMM 14th Underground Operators Conference 2023, Brisbane, Qld, pp 156-175.

Pratt, A G L, 2024. Project Readiness for Mining Operations, Proceedings of the 9th International Conference on mass Mining / Kiruna / Sweden / 17-19 September 2024, Ed. D Johansson and Håkan Schunnesson, pp 1617-1643.

Rey, S, 2019. Readiness: The Missing Key Between Strategy and Execution, https://trainingindustry.com/articles/strategy-alignment-and-planning/readiness-the-missing-key-between-strategy-and-execution/, accessed 17/05/2022.