PXRF advances in geochemical applications

Background: Recent developments in pXRF instrumentation capabilities

Since the capabilities report titled ‘Quality Control Assessment of Portable XRF Analysers’ was published by Hall (2014), a lot has happened in the Portable X-ray Fluorescence (pXRF) arena.

Especially in Australia, universities, CSIRO and service companies have taken a leading role to push the technology with pXRF vendors as part of a variety of projects, leading to a number of excellent publications. There was a 202 paper by Adams et al published in Geochemistry: Exploration, Environment, Analysis, which was an excellent example of comparing new instrument capabilities; and a book edited by Drake and MacDonald titled Advances in Portable X-ray Fluorescence Spectrometry: Instrumentation, Application and Interpretation.

The biggest change in the technology in recent times was the introduction by KETEK (a German manufacturer) of a silicon drift detector (SDD) with a graphene window, replacing the traditional coated beryllium window. This increased sensitivity beyond magnesium (Mg) for units with a helium (He) flush – e.g., sodium (Na) and even fluorine (F). For the ‘normal’ air-based application, this change created a 10x improvement of signal on average for Mg (depending on vendor and model). All major vendors have now adopted the new window in all or some models.

The second improvement also concerned the detector, but improved the capacity of signal processing. Currently some units can exceed 500,000 counts per second (cps) at the same resolution that prior units could process 100,000 cps. This allows for faster assays and the ability to increase the tube power from two up to five watts.

pXRF as an alternative for exploration and grade control assays

A pXRF with site-specific calibration or stringent matrix matched standardisation, as well as good quality assurance/quality control (QA/QC), can achieve a quality and reproducibility which is suitable for uses such as modelling, rig vectoring, grade control and geometallurgical applications.

XRF in general is a ‘complete assay’: that is, it measures the total content of arsenic (As) or iron (Fe) in the sample. However, it cannot distinguish between different oxidation states or bindings.

While pXRF does not replace the classical/accepted Inductively Coupled Plasma Optical Emission Spectrometry/Mass Spectrometry (ICP OES/MS)-based schemes based on fusion digest, it provides a much better view of the complete sample, unlike Aqua Regio (AR) or multi-acid digests with an ICP OES/MS finish.

For the very cost-conscious exploration companies, which focus on the extractable (e.g. ‘available’ base metals and gold) combining pXRF with their selected AR digest ICP-OES/MS finish is a great solution.

The pXRF ‘complete’ sample data from Mg to U compliments the AR data and enables the user to make lithology assessments and rock norm calculations (e.g. CIPW norm).

Similarly, if one uses a partial 4 acid digest or multi acid digest, a rapid loose powder based pXRF assay can provide the Si, Ti and Zr (unavailable and partial from the ICP) needed for modelling rock types.

This can in some instances be cheaper (and always faster) then a fusion digest followed by ICP-OES/MS finish.

pXRF does not replace the traditional borate fusion major and minor elements assay (i.e. whole rock assay) by Wavelength Dispersive XRF (WD-XRF). The accuracy and repeatability of this fully traceable assay and the wide range of concentration from 0.01 to 100 per cent is unmatched, even compared to fusion digest ICP.

Due to the limited availability of Certified Reference Material, pXRF is limited in range, e.g. Arsenic < 10%, unlike an ICP or borate fusion based XRF setup which can rely on synthetic homogenous mixtures.

pXRF are calibrated (in the factory, or by SGS) using loose powder mounts or, for some projects, pressed pellets when higher accuracy is required.

As outlined in the previous section, pXRF is still rapidly evolving with respect to size, reliability, sensitivity, and consistency as well accuracy of the vendor provided calibrations.

Case study using a generic geochemical setup

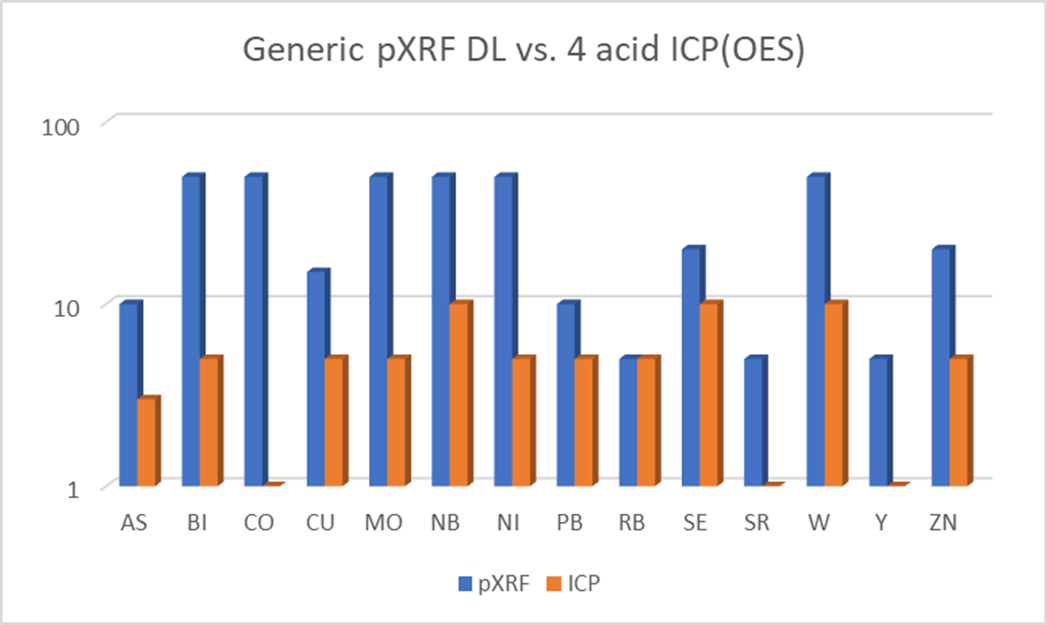

Let’s look at a generic geochemical setup employing a dual beam (excitation condition setting) as might be available on ‘older’ 4-watt pXRF units in comparison to a typical 4 acid digest ICP scheme (GE_ICP40Q20).

Starting by comparing detection limits, which for exploration ‘quality’ methods are also the lower reporting range for some typical pathfinders and base metals, assay time for the setup shown is less than two and a half minutes on a typical pXRF unit and uses a 2-beam setup: high voltage (e.g. 50 kV) with filter for Manganese (Mn) to Uranium (U) and low voltage (e.g. 15 kV) with no filter to detect Magnesium (Mg) to Manganese (Mn).

For this setup, the pXRF is in the 10 ppm region with some elements as high as 50 ppm, while the ICP OES is consistently lower (up to 10x). The sweet spot (< 10 ppm detection limit) is for Lead (Pb), Rubidium (Rb),Strontium (Sr),Yttrium (Y), Zirconium (Zr) and Niobium (Nb). The latter elements and ranges are important as a ‘fingerprint’ for geological deposition areas (in sediments) or for igneous materials (e.g. obsidian sourcing).

For the upper range limit (UL), the ICP usually has a wider range for not so common elements, as it is calibrated using artificial liquids. The pXRF has to rely on available assayed material. The ICP setup for mineralised samples is different and can require that samples be assayed a second time with a different method. These above limits samples will either be reported as >1% (or whatever the upper range/limit is), or are re-assayed using a scheme with a higher upper limit. pXRF can have a wider range only limited by the chosen reference material and sometimes by the chosen settings and calibration methodology.

This Bulletin article is an edited excerpt from a longer white paper – those interested in reading the full paper can contact the author via the SGS website here.

Reference

Hall G, 2014. ‘Evaluation of portable X-ray fluorescence (pXRF) in exploration and mining: Phase 1, control reference materials’. Geochemistry: Exploration, Environment, Analysis, Vol. 14, 2014, pp. 99–123 http://dx.doi.org/10.1144/geochem2013-241.