Transforming the mining industry through data and digital innovation

From digital twins to quantum computing

In this article we delve into the advanced technologies that hold the potential to transform the mining and metals industry. We explore the application of digital twins, the use of artificial intelligence (AI) and machine learning, and the concept of collaborative innovation.

Digital twins in mining

Digital replicas of physical assets, processes, and systems can revolutionise decision-making and optimisation in the mining sector.

There are four types of digital twins — analytics, asset, process, and system twins — that help solve problems and offer unique insight. These twins each offer a unique perspective and opportunity to optimise mining operations, reduce costs, and enhance productivity. They can uncover value losses and unrealised potential within the mining value chain, making them a critical component of the industry's future. Each are tailored to address industry-specific challenges:

- Analytics twin:A pivotal cornerstone, the analytics twin delves into data intricacies to extract actionable insights. Informed by data analysis, industries can make informed decisions, steering strategies toward optimal outcomes.

- Asset twins:Rather than an entity synonymous with complexity, asset twins provide practical solutions. These virtual counterparts of physical assets delve into machinery behaviour, facilitating proactive maintenance and prolonging asset life.

For example, in collaboration with a leading gold mining company, Hatch Digital undertook the development of an autoclave digital twin application aimed at enhancing operational efficacy and decision-making processes. The digital twin delivered real-time estimations of oxygen utilisation within each compartment and agitation stage of the autoclave. It indicated if sulphide oxidation rates were running ahead of reactive sulfide feed rate or inventory within the autoclave, facilitating proactive adjustments to optimise throughput.

The digital twin was deployed across all autoclaves at the client site, contributing to a substantial five per cent increase in production throughput and exemplifying its tangible impact on operational performance in mining.

- Process twins:Grounded in real-time data and sophisticated models, process twins optimise industrial processes. By targeting inefficiencies, this twin empowers industries to achieve higher levels of productivity and helps inform better decisions surrounding complex assets.

- System twins:Navigating intricate systems, system twins orchestrate seamless interactions among components. This orchestration enhances system-wide performance and uncovers opportunities for holistic advancements.

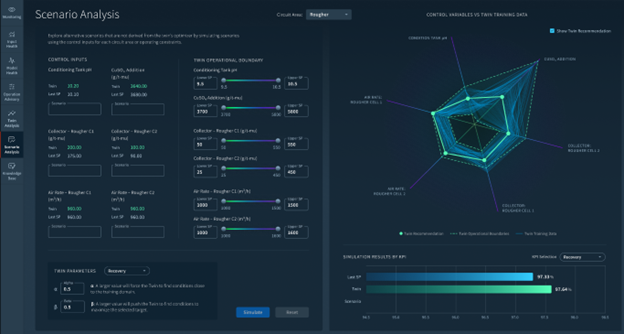

For example, Hatch conducted a project to optimise the base metal sulfide flotation circuit for a large zinc-lead mine, aiming to enhance recovery and concentrate grade while reducing operational costs through a novel flotation digital twin solution. Leveraging modern machine learning and AI techniques, our digital and minerals processing experts developed a deep learning architecture capable of accurately predicting grade and recovery performance in near real-time. They successfully identified specific operating setpoints for different feed types, resulting in a significant improvement in zinc recovery and enhancement in combined rougher scavenger concentrate grade.

This achievement underscores the effectiveness of the flotation digital twin, powered by AI-driven decision automation, in unlocking operational efficiencies and driving sustainable competitiveness in the minerals processing industry.

Figure 1. An example of a flotation twin dashboard used by mining process operators.

The role of artificial intelligence and quantum computing

AI has been a buzzword in many industries, but its application in mining and processing extends beyond marketing. By transforming the way daily operations are handled, mining professionals are turning to AI to make informed decisions by analysing vast datasets and identifying patterns and anomalies. Some examples are explored below.

Artificial intelligence

Image and sensory recognition

AI-powered recognition systems can analyse images from mining operations, such as geological formations or equipment conditions, to identify potential issues and opportunities for improvement.

Teams of experts at Hatch have developed techniques for monitoring mining processes, like shaft sinking, through the integration of computer vision and AI technologies. Our system automates the labour-intensive task of data collection and identifying various mining activities, offering real-time insights with precise event timestamps.

Leveraging our domain expertise, we translate these event timestamps into tailored dashboards of mining performance, pinpointing discrepancies between actual progress and the mining plan to enhance overall productivity. This transformative approach not only reduces costs associated with manual surveillance but also streamlines operations, ensuring efficient project execution.

Related to the above is sensory recognition, in which vision-based systems recognise events and interpret the differences in output. This improves productivity and decision-making.

Process optimisation

AI can optimise various processes, from ore extraction to logistics, by continuously analysing data and making real-time adjustments for maximum efficiency and resource utilisation. An example of this in the mining industry can be seen with the continuous tracking of iron ore on conveyor belts. This data feeds into a process optimisation model that sequences the starting and stopping of conveyor belts to minimise downtime while prioritizing safety.

Machine learning

There are a whole host of problems with processing assets and the number of variables such as ore grade, temperature, and conditions. Machine learning provides the ability to calibrate outcomes — an exciting thing to explore.

For example, where the demand for consistent, high-value coal feed necessitated overcoming fluctuations in mine qualities, volumes, and equipment delays, a digital solution involved a two-level optimisation framework, integrating weekly coal blend planning and daily stockpile scheduling for stacker/reclaimer operations. Leveraging advanced machine-learning models, the solution established an integrated forecast for mine quality and volume, enhancing prediction accuracy. Critical constraints, including coal availability, transport capacity, and operational limitations, were incorporated into the framework. The result is a streamlined process that maximises the volume of reclaimable coals while minimising deviations from target quality, enabling optimal performance.

Safety and risk concerns

AI can also analyse data from sensors, monitoring worker and equipment conditions to increase safety and reduce risks by identifying potential hazards and suggesting preventative measures.

Quantum computing

Quantum computing, over time, also presents revolutionary potential. With design systems that can solve multiple problems in parallel, process unique quantum algorithms, and perform quantum annealing, in time this cutting-edge technology could take AI and data analysis to new heights. It has the potential to solve complex mining problems that were previously insurmountable, ultimately changing the way mining companies operate.

One example of this is the key role quantum computing can play in modelling geological conditions under the earth’s surface to ensure mines effectively extract materials. Quantum computers can take in far richer and greater data from a wider range of sources than classical computers and know how to search and apply that data effectively. They know how to interpret satellite imagery and on-the-ground data to produce a more accurate model of the earth than is currently possible, transforming mining in the following ways:

- Efficient data processing. Quantum computers can process and interpret vast amounts of data more effectively than classical computers, providing precise insights into geological conditions.

- Resource optimization. By minimising wasted materials and equipment and reducing mine downtime, quantum computing can maximise resource flow, ultimately enhancing operational efficiency.

- Digital autonomy. As mining processes become 'smarter' and more connected, quantum computers can monitor and optimise every aspect of mining operations, ensuring digital autonomy and maximum efficiency.

Figure 2. Using the digital twin to run optimisation scenarios can improve the production process and reduce costs by predicting the outcome using different operating parameters.

Collaborative innovation in the mining industry

Collaboration is integral to the mining industry’s transformation. It’s not just about mining companies working together; it’s also about companies outside the mining sector contributing to the evolution and disrupting current leaders by applying innovative solutions. What does truly collaborative innovation look like? Here are some considerations:

- Outside expertise. Companies from other sectors can provide domain expertise and digital knowledge, which can be instrumental in addressing mining-specific challenges.

- Diversity of thought. Fresh perspectives can lead to innovative approaches and solutions that may have been overlooked within the industry.

- New skillsets. Collaborators from diverse backgrounds bring a mix of skills and knowledge, enriching the mining industry’s problem-solving capabilities.

While the barriers to entry in mining are high, the changing narrative around the industry, with a focus on sustainability and electrification, is drawing attention from tech companies and investors. The mining industry is not merely about extracting resources but transforming the world, making it an exciting field for innovation. And with the right mix of domain expertise and digital know-how, there's an opportunity to drive substantial change.

Looking ahead: the confluence of technologies

The mining industry is at the cusp of a significant transformation. The convergence of AI, quantum computing, and digital twins presents unparalleled opportunities for the sector. With a focus on deep domain expertise and digital innovation, the mining industry can overcome its productivity gaps and continue to provide the resources that drive the modern world.

By embracing data-driven innovation, collaborating with startups, and harnessing advanced technologies, the mining industry can secure a more sustainable and prosperous future.

Want to learn more? You can listen to the Hatch podcast or contact Hatch here.