Turning mine waste into value – sustainable strategies for modern mines

Mining activities generate an enormous amount of waste, posing significant environmental and safety risks.

Mining activities generate an enormous amount of waste, posing significant environmental and safety risks.

Traditional methods of tailings and waste management must smarten up. This article explores smart strategies for turning mine waste into valuable resources, and helping improve sustainability, economic viability, safety and environmental benefits.

Problem statement

The mining industry produces approximately 100 billion tonnes of waste annually, 10 per cent of which is tailings (Vuillier et al, 2021). These are generally stored in an increasing number of high-risk tailings dams, posing permanent environmental and safety hazards.

Furthermore, mineral deposits are becoming less accessible and depleted, leading to more waste. The financial and operational complexities of managing mine waste are growing, driven by stricter environmental regulations and reduced risk appetite due to recurring failures.

Plus an increasing global population, accelerating development, and necessary carbon dioxide reduction is driving up the demand for minerals and metals and exacerbating the production of mine waste.

Potential for sustainability opportunities

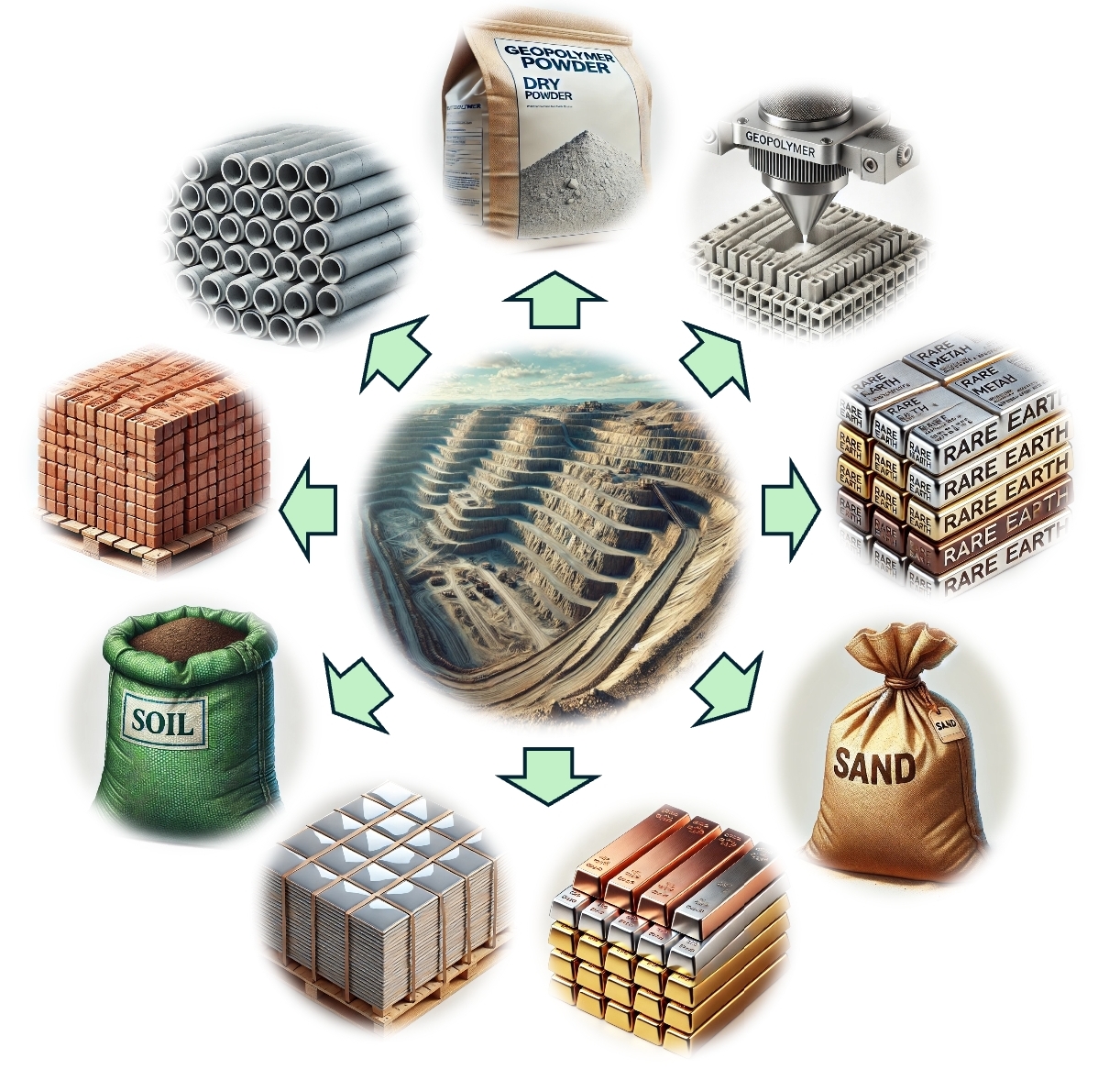

The mining industry has a unique opportunity to mitigate its environmental impact by turning waste into vast amounts of resources, contributing to a safer and more sustainable future. By rethinking waste management strategies, these valuable resources can be created. This approach aligns with global trends towards carbon reduction, sustainability and circular economy principles.

In other words, the 100 billion tonnes of mine waste produced annually can be viewed as a resource rather than a liability. This waste contains materials that can be repurposed for many industries, as outlined below.

- Construction: The global construction industry demands approximately 40 billion tonnes of raw materials each year. Waste rock and tailings can meet a significant portion of this demand.

- Soil rehabilitation: with 100 billion tonnes of soil washed out annually, there is an opportunity to use mine waste for soil rehabilitation and agricultural applications.

- Industrial raw material: Many industries require minerals and metals that can be sourced from mine waste that are already mined, crushed and ground.

Transforming tailings into valuable materials

Tailings, which are finely ground rock particles, can be decontaminated and repurposed for more sustainable practices by transforming them into clean, useful materials. This section explores various methods for converting tailings into valuable resources, highlighting the benefits and potential applications.

Two of the key benefits are reducing the volume of waste storage and creating new revenue streams. Some opportunities include:

- production of fine sands and other materials suitable for construction.

- production of techno-soils for agriculture, reforestation and ecosystem restoration.

- extraction of residual metals through simple reprocessing techniques.

- production of cementitious materials, an alternative to traditional cement.

More options are discussed below including options for remote mines. By exploring these opportunities, the mining industry can contribute to sustainability while changing the traditional waste management practices.

Recovering metals from tailings

A substantial portion of these finely ground material consists of silicates (up to 80%), with oxides, sulfides, and chlorides making up about 10%, the rest being alkaline minerals and carbonates. Tailings contain valuable metals and minerals that can be extracted and repurposed by simple methods such as:

- gravity separation for recovering heavy metals such as iron, gold, copper, cobalt, Nickel, lead and many more.

- magnetic separation for extracting ferromagnetic metals.

- bio-leaching utilising microorganisms to leach metals from tailings, an environmentally friendly method for extracting metals such as copper, nickel, and cobalt.

- leaching useful for recovering a wide range of elements, including rare earth metals.

Plus the extraction of sulfides, oxides and chlorides contributes to decontaminating the mine waste.

Transforming tailings into prefabricated construction materials

Tailings are generally rich in alumino-silicates, a raw material which can be used to create high value, reduced carbon footprint manufactured construction material, educing the need for quarries. Potential materials include:

- bricks, tiles and ceramics.

- concrete and precast elements such as segments for tunnels, pipes, beams and walls.

- Geopolymers, which offer a sustainable and high-performance alternative to traditional concrete. Simple manufacturing processes using low-temperature purification, dissolution and polymerisation can be carried out at room temperature and offer superior mechanical, heat, and chemical resistance compared to conventional concrete.

Collaboration with construction material manufacturers is essential for developing high-value products produced close to mine sites. The high value of these products can absorb transportation costs, even for remote mines, allowing in-demand items to be dispatched to major urban centers across Australia and overseas. For example, the market for precast concrete in the Asia Pacific region is growing, reaching USD 42.3 billion in 2023 (Grand View Research, 2024).

Benefits

Economic benefits

Transforming mine waste into valuable resources offers substantial economic benefits, including:

- Reduced size of Tailings Storage Facilities (TSF) and associated costs such as maintenance, monitoring, repair and closure costs.

- New revenue streams related to raw materials, techno-soils, construction materials and recovered metals. These can be sold or created collaboratively by industries and governments, enhancing the financial sustainability of mining operations. The repurposing phase can be designed, financed, built and operated by industry partners.

- Reduced environmental and financial risks associated with tailings dam failures and long-term storage liabilities. This not only lowers potential clean-up costs and the likelihood of regulatory penalties but also increases investors confidence.

- Local economic benefits by collaborating with local industries and establishing manufacturing plants near mining sites. Companies can create jobs and stimulate economic growth in mining regions, leading to the development of vibrant, sustainable communities.

Environmental benefits

Significant environmental advantages can include:

- The reduced need for traditional TSFs reduces the risk of dam failures and environmental contamination.

- Lower environmental footprint: Repurposing tailings reduces the need for quarries by providing already crushed and ground material, thereby minimising the environmental impact of mining and quarrying operations. This aligns with circular economy principles such as resource efficiency and waste reduction.

- Enhanced ecosystem health: Techno-soils help ecosystem restoration, improve local environments, and restore habitats, biodiversity and soil quality.

- Collaboration and Innovation: Collaboration between mining companies, industries, regulators, legislators and research institutions drives innovation in sustainable practices. These partnerships can lead to the development of new technologies and processes that further reduce the environmental impact of mining and other industries.

Social implications

Repurposing mine waste can also create positive social implications, such as:

- Developing new industries around repurposing mine waste creates job opportunities, leading to sustainable economic development and improved living standards for local communities.

- Developing industries utilising mine waste in mining regions can create sustainable communities and vibrant economic hubs.

- Helping to create harmonious relationships with local communities and investors by demonstrating a commitment to sustainability, responsible waste management and engagement with stakeholders by building trust and supporting social license to operate.

- Collaborations with academic institutions provide educational opportunities and support research in sustainable mining practices. This enhances the knowledge base and skill set of the local workforce.

Case studies: Demonstrating readiness

Three case studies highlight successful projects in repurposing mine waste, demonstrating the feasibility and benefits of these approaches:

- The NEMO (Near-zero-waste recycling of low-grade sulphidic mining waste) Project, funded by the EU's Horizon 2020 program, developed and demonstrated technologies for near-zero-waste treatment of sulfidic mining waste. They reached their target on three mine sites, reducing the volume of waste by more than 95% and extract critical minerals.

- The BHP Tailings Challenge: The Challenge identified innovative solutions for repurposing tailings. I was part of a consortium, selected to repurpose tailings using bio-leaching, carbon sequestration, cementless construction blocks and fertile soil. This project demonstrated that 90% of tailings could be safely decontaminated and repurposed.

- In Australia, I developed a tailings chemical and mineralogical testing approach to identify simple decontamination techniques, metal extraction and collaboration with local manufacturer to re-use large amount of waste, demonstrating a potential for 90% volume reduction.

Conclusion

The future of sustainable mining lies in our ability to transform what was once considered waste into valuable resources. As highlighted through the smarter approaches and successful case studies discussed in this article, the mining industry has a significant opportunity to turn mine waste into a driver of economic growth and environmental sustainability.

By adopting simple, safe and proven technologies, the industry can reduce its environmental footprint, increase safety, lower operational costs, and create new revenue streams. The case studies demonstrate that these concepts are not only feasible but also highly beneficial.

This approach addresses several critical challenges, including reduction of high-risk tailings dams, the scarcity of raw materials, and the regulatory and financial burdens associated with traditional waste storage. Moreover, it fosters job creation, supports local communities, and enhances the relationship between mining companies and their stakeholders.

As we move forward, the commitment to sustainability will require continued collaboration among resources professionals, mining companies, industries, regulatory authorities, academic institutions, and local communities. Together, this solution can become mainstream and ensure a positive contribution to a sustainable and resilient future.

The path to a greener, more sustainable mining industry is clear. Viewing mine waste as a resource can unlock tremendous potential for environmental and economic benefits. The time to act is now, and with the strategies and technologies at our disposal, we are well-equipped to lead this transformative change. Let us embrace this opportunity to build a future where mining operations are not only profitable but also harmonious with the planet we strive to protect.

References

Grand View Research, 2024. ‘Asia Pacific Precast Concrete Market Size, Share & Trends Analysis Report By Product (Structural Building Components, Transportation Products), By Application (Residential, Commercial, Infrastructure), By Country, And Segment Forecasts, 2024 – 2030’, Online. Available from: https://www.grandviewresearch.com/industry-analysis/asia-pacific-precast-concrete-market-report

Vuillier C, Price A, Ingwersen M, Peys A and Menard Y, 2021. ‘The Future of Mining with Zero Mine Waste’. The Southern African Institute of Mining and Metallurgy (SAIMM), Global tailings Standards and Opportunities for the Mine of the Future, Rustenburg, South Africa.